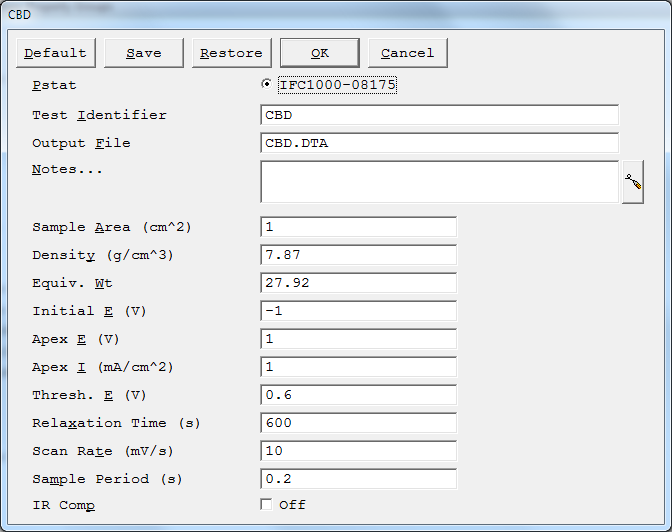

Corrosion Behavior Setup Parameters

Here is a Corrosion Behavior Diagram Setup dialog box complete with its default parameters.

The starting point for the first potential sweep during data-acquisition. This is generally a potential where about 10 mA of cathodic current flows. The allowed range is ±10 V with a resolution of 1/8 mV. Its accuracy depends on the setting.

The potential sweep at which the scan reverses during the first scan. The scan may reverse before the Apex E, if the Apex I is exceeded.The allowed range is ±10 V with a resolution of 1/8 mV. Its accuracy depends on the setting.

Sets a current at which the initial CBD scan reverses. If the scan is beyond the Thresh. E and the absolute value of the cell current exceeds Apex I, the scan reverses regardless of the Apex E setting. The units for the Apex I are mA. The upper limit is ± your potentiostat’s rated current. A practical lower limit is about 100 nA.

The point in the scan at which the Apex I test for scan-reversal is enabled. When the cell potential is below the Thresh. E, Apex I testing is disabled, when it is above the Thresh. E, Apex I testing is enabled.The allowed range is ±10 V with a resolution of 1/8 mV. Its accuracy depends on the setting.

The time that the sample will be held at open circuit between the scans. The relaxation may stop before the Relaxation Time if the Stability criterion is met. The units for the Relaxation Time are seconds. The minimum time is one second, the maximum time is 4000 seconds.

The speed of the potential sweep during data-acquisition. The same sweep rate is used for all three sweeps in the CBD experiment.The Scan Rate is entered in units of mV/s. A practical upper bound on the Scan Rate is 100 mV/s. Higher Scan Rates may run, but yield unreliable data because the potentiostat’s compensation and filtering are set for long time constants.A lower bound on the Scan Rate is given by the minimum Step Size divided by the longest Sample Period. For scans shorter than 2 V, the slowest Scan Rate is 52.1 nV/s or 0.1875 mV/hour. Multiply these limits by four for scans longer than 2 V.

The spacing between data points. It also helps determine the Step Size of the staircase ramp and the Number of Points in the data curves.The Sample Period sets the length of a step. The height of a step depends on both the Scan Rate and the Sample Period. You can calculate the Step Size and the Number of Points in a scan from:

Step Size = Scan Rate × Sample Period

Number of Points = Scan Range / Step Size

The Step Size is rounded to the resolution of the D/A converter making the steps. The resolution of the D/A converter depends on the type of potentiostat you use. Consult your potentiostat manual for more information. A typical Step Size for a Corrosion Behavior Diagram scan is between 1 and 5 mV/step. The default DC Corrosion CBD parameters yield a Step Size of 2 mV.The maximum Number of Points in each scan equals a constant set in GLOBALS.EXP. Determining the Number of Points requires the scan range. Unfortunately, in the CBD experiment the scan range to use is not obvious. In the initial scan, use the maximum scan range (twice the difference between the Apex E and the Initial E) for the Scan Range. You may have fewer points if the scan reverses early.The scan range for the final scan is also unknown ahead of time. We start a scan relative to Eoc and end at an absolute potential. Fortunately, this scan is always shorter than the initial cyclic scan, so if the initial scan does not exceed the maximum Number of Points the final scan will not either.The units used for the Sample Period are seconds. The shortest Sample Period we recommend is 0.1 second. The longest Sample Period allowed is 600 seconds.

Comments are closed.