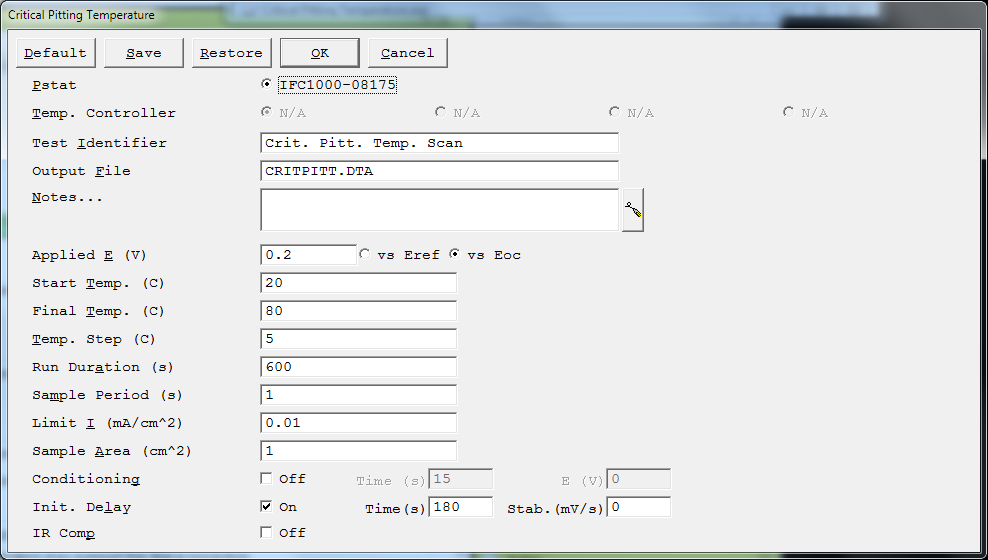

Common Setup Parameters for Critical Pitting Temperature

Each of the following are setup parameters common among the Critical Pitting Temperature techniques.

Pstat

- Selects the potentiostat/galvanostat to perform the experiment. Each labeled button corresponds to an installed potentiostat. When a potentiostat is selected, its corresponding button is filled in.In a multiple-potentiostat system, change the potentiostat selection by clicking on a Pstat‘s button using the mouse. From the keyboard, tab down until a dotted line appears around one of the Pstat labels, then hit the spacebar to select among the potentiostats. Only one potentiostat can be selected at a time, so selecting one potentiostat deselects another one.

Temp. Controller

- Selects the temperature controller to perform the experiment. Each labeled button corresponds to an installed temperature controller. When a temperature controller is selected, its corresponding button is filled in. Most Critical Pitting Temperature systems have only one temperature controller, so this parameter is not required. However, you can install support for more than one type of controller.

Test Identifier

- A string that is used for two purposes. The Test Identifier parameter is written to the data file, so it can be used to identify data in database or data-manipulation programs. The Test Identifier string is also used as the title for both real-time plots and plots in data-analysis packages.The Test Identifier string defaults to a name derived from the technique’s name. While this makes an acceptable curve-label, it does not generate a unique descriptive label for a data set.The Test Identifier string is limited to 80 characters. It can include all normally printable characters, including numbers, upper- and lower-case letters, and most normal punctuation including spaces.

Output

- The pathname of the file in which the output data are written. It can be a simple filename with no path information. In this case the output file is located in the default data directory. The default data directory is specified in the Gamry.INI file under the [FRAMEWORK] section with a Key named DataDir. This default pathname can be changed using the Path command under the Options menu. It can also include path information, such as C:DATAYOURDATA.DTA. In this example, the data are written to the YOURDATA.DTA file in the DATA directory on drive C.

- The default value of the Output File parameter is an abbreviation of the technique name with a .DTA filename extension. We recommend that you use a .DTA filename extension for your data filenames. The data-analysis software assumes that all data files have .DTA extensions.

NOTE: The software does not automatically append the .DTA filename extension. You must add it yourself.

- If the script is unable to open the file, an error message, Unable to Open File, appears. Common causes for this type of problem include:

- An invalid filename.

- The file is already open under a different Windows® application such as Excel®.

- After you click the OK button in the error window, the script returns to the Setup box where you can enter a new filename.

Notes…

- Allows you to enter several lines of text that describe the experiment. A typical use of Notes… is to record the experimental conditions for a data set.

- Notes… defaults to an empty string.The Notes… string is limited to 400 characters. It can include all printable characters including numbers, upper- and lower-case letters, and most normal punctuation including spaces. In addition, it can include new-line characters entered as ctrl + enter. tab characters are not allowed in the Notes… string.Notes… are not saved or recalled with the other parameters.

Sample Area

- The surface area of the sample (in cm²) exposed to the solution and thus available to be corroded.The software uses the Sample Area parameter to calculate current density. If you do not want to enter an area, we recommend that you leave this parameter at its default area of 1.00 cm².

NOTE: Do not enter a value of zero!

Conditioning

- You may condition the electrode as the first step of the experiment. Conditioning ensures that the metal sample has a known surface state at the start of the experiment. You may condition to remove an oxide film from the electrode or to grow one. Conditioning is done potentiostatically for a known time.

- Conditioning is controlled by a single line in the Setup dialog box. This line contains the Conditioning switch and the Conditioning Time and Conditioning E fields. Turn the conditioning on or off with the Conditioning switch check box. Conditioning E is the potential applied during the conditioning phase of the experimental sequence.

- The conditioning potential has an allowed range of ±8 V. The resolution is 1/4 mV. If you have enabled IR-compensation for the data-acquisition phase of your experiment, it is also turned on during conditioning.Conditioning E is always specified as vs. Eref, because the open-circuit potential is not measured until after Conditioning is completed.The Conditioning Time is the length of time that the sample is potentiostatted at the Conditioning E. The units for Conditioning Time are seconds. The minimum time is one second. The maximum time is 400000 seconds (more than 4 days). Below 1000 seconds, the time resolution is one second. Between 1000 seconds and 10000 seconds, it is 10 seconds. Above 10000 seconds, it is 100 seconds.

IR Comp

- Gamry potentiostats are able to estimate uncompensated voltage-drop caused by cell resistance. They do so by performing a current-interrupt experiment after every data point. You can set the Setup IR Comp checkbox to either On or Off. Turning on IR Comp causes the applied E to be adjusted for the estimated IR-drop.

Comments are closed.