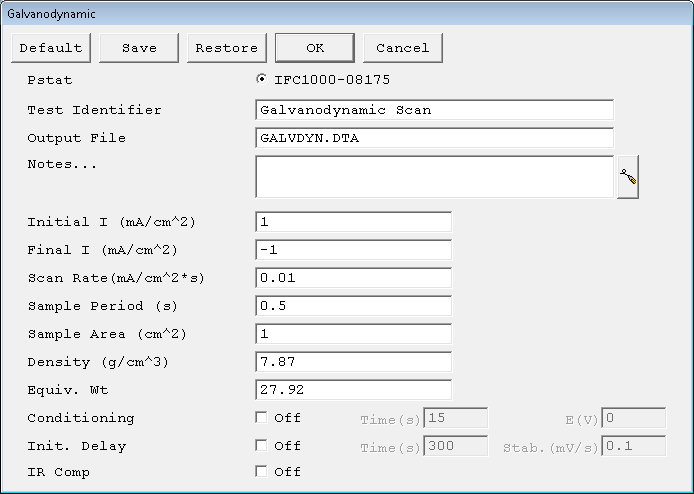

Galvanodynamic Setup Parameters

Here is a Galvanodynamic Setup dialog box complete with its default parameters.

The starting point for the current sweep during data-acquisition. The allowed range is ± your potentiostat’s rated current. Its accuracy and resolution depends on the settings for both the Initial I and Final I parameters, as described below.

The ending point for the current sweep during data-acquisition. The allowed range is ± your potentiostat’s rated current. Its accuracy and resolution depends on the settings for both the Initial Iand Final I parameters.Both Initial I and the Final I (and all the currents between them) are set using one current range on the galvanostat. The current range is selected so that the largest absolute current requested is on scale. For example, using a Reference 3000 potentiostat, if the Initial I is 0.1 mA and the Final I is 25 mA, the galvanostat operates on the 30 mA range throughout the experiment. The resolution and accuracy is that of the 30 mA range.

The speed of the current sweep (actually a staircase ramp) during data-acquisition, in units of mA/s. A practical bound on the Scan Rate is about 10% of the full-scale current range per second. Higher Scan Rates may run, but yield unreliable data because the potentiostat’s compensation and filtering are set for long time constants. A lower bound on the Scan Rate is given by the minimum Step Size and the longest Sample Period. The minimum Step Size is 0.0033% of full-scale current and the longest Sample Time is 715 seconds. The slowest Scan Rate is therefore 55 ppm of full-scale current per second, or 0.02% of the full-scale current per hour.

NOTE: The most sensitive current range on your potentiostat is generally not available in controlled-current experiments.

Sample Period

The spacing between data points, in seconds. The shortest Sample Period we recommend is 0.25 second. The longest Sample Period allowed is 715 seconds.

The Sample Period also helps determine the Step Size of the staircase ramp and the Number of Points in the data curve. The length of a step in the staircase ramp is the Sample Period directly. The height of a step depends on both the Scan Rate and the Sample Period. Calculate the Step Size and the Number of Points in the scan from:

Step Size = Scan Rate × Sample Period

Number of Points = Scan Range / Step Size

Step Size is rounded to the resolution of the D/A converter making the steps. The resolution of the D/A converter is dependent on the type of potentiostat you are using. Consult your potentiostat manual for more information. A typical Step Size for a Galvanodynamic scan is about 0.2% full-scale current/step. If the Step Size has to be rounded to fit the resolution of the D/A converter, the Sample Period is also adjusted so that the Scan Rate is correct.The Number of Points must be less than 262143. If you have more points, the experiment will abort just before the scan phase of the sequence.Here is an example.

1. Assume a sweep from –10 mA to +25 mA, at 0.1 mA/s.

2. Take data at 2 seconds/point.

3. Step Size is 0.1 mA/s × 2 s/point = 0.2 mA/step.

4. The program chooses the 30 mA range, so the D/A resolution is 0.00333% of 30 mA or 0.001 mA/bit. Each step is therefore 200 bits on the D/A converter.

5. The Number of Points in the scan = 35 mA/0.2 mA/step, or 175 points.

Comments are closed.