Pstat

|

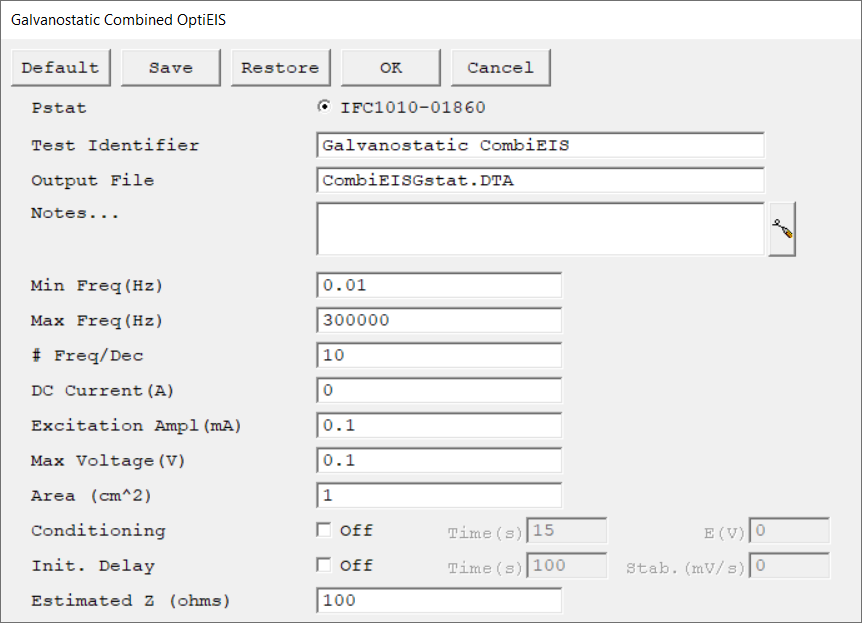

Select the potentiostat/galvanostat to perform the experiment. Each radio button corresponds to an installed potentiostat. You can select only one potentiostat at a time. Potentiostats that are already in use are marked with an asterisk. They can be selected but cannot be used.

|

|

Test Identifier

|

A string that is used as a name. It is written to the data file, so it can be used to identify the data in database or data manipulation programs. The Identifier string defaults to a name derived from the technique's name. While this makes an acceptable curve label, it does not generate a unique descriptive label for a data set. The Identifier string is limited to 80 characters. It can include almost any normally printable character. Numbers, upper- and lower-case letters, and the most common punctuation characters including spaces are valid.

|

|

Output File

|

The name of the file in which the output data are written. By default, it is saved in the default file directory.

The input can be a simple file name with no path information. In this case the output file is located in the default file directory. The default file directory is specified in the Gamry.INI file under the [Framework] section with a Key named DataDir. The default path can be changed using the Path command in the Options menu. It can also include path information, such as C:\MY GAMRY DATA\YOURDATA.DTA. In this example, the data are written to the YOURDATA.DTA file in the MY GAMRY DATA directory on drive C. The default value of the Output File parameter is an abbreviation of the technique name with a *.DTA filename extension. We recommend that you use a *.DTA file name extension for your data file names. The data analysis package assumes that all data files have *.DTA extensions.

If the script is unable to open the file, an error message box, Unable to Open File, is generated. Common causes for this type of problem include:

•Invalid file name.

•The file is already open under a different Windows® application.

•The disk is full.

After you click the OK button in the error box, the script returns to the Setup where you can re-enter the file name.

|

|

|

Notes...

|

Enter several lines of text that describe the experiment. A typical use of Notes is to record the experimental conditions for a data set.

Notes defaults to an empty string and is limited to 400 characters. It can include all printable characters including numbers, upper- and lower-case letters, and the most common punctuation including spaces. Tab characters are not allowed in the Notes string. Press the Notes button on the right-hand side to open a separate Notes dialog box.

|

|

Min Freq.

|

The Min Freq. parameter defines the lowest frequency of the scan.

|

hertz (Hz)

|

Max Freq.

|

Max Freq. defines the highest frequency component of the scan. This frequency cannot be greater than Min Freq. × 4096 and must be less than 9375 Hz.

|

hertz (Hz)

|

# Freq/Dec

|

A rough definition of the data density in the final impedance spectrum. Because of the mathematics involved in OptiEIS, the minimum allowed value is 10 and the maximum value is 22. The lowest frequency decade is fixed at nine frequencies because of mathematical constraints.

|

|

DC Current

|

The constant potential applied to the cell throughout the multi-sine scan. The multi-sine signal is summed with the Excitation Amplitude.

|

amperes (A)

|

Excitation Ampl

|

The base amplitude value which is used to calculate the multi-sine AC signal. Individual sine waves within the multi-sine signal can have different amplitudes, but the final signal cannot exceed the specified value.

|

mA

|

Max Voltage

|

The initial voltage-measurement range of the galvanostat. If necessary, the voltage measurement range is adjusted during the signal-optimization phase, but this adds extra time to the experiment.

|

volts (V)

|

Area

|

The surface area of the sample that is exposed to the solution. The software uses the sample area to calculate the current density and corrosion rate (if applicable). If you do not want to enter an area, we recommend that you leave it at the default value of 1.00 cm².

|

Do not enter a value of zero!

|

|

cm2

|

Conditioning

|

You may condition the electrode as the first step of the experiment, e.g., to remove an oxide film from the electrode or to grow one. Conditioning ensures that the metal sample has a known surface state at the start of the experiment. This step is done potentiostatically for a set amount of time.

Turn the conditioning phase On or Off with the Conditioning switch check box. Conditioning E is the potential applied during the conditioning phase of the experimental sequence. The conditioning potential has an allowed range of ±8 V. The resolution is 0.25 mV. If you have iR-compensation enabled for the data acquisition phase of your experiment, it is also turned on during conditioning. Conditioning E is always specified vs. Eref, because the open-circuit potential is not measured until after Conditioning is completed.

The Conditioning Time is the length of time that the sample is potentiostatted at Conditioning E. The minimum time is 1 s and the maximum time is 400000 s (more than 4 days). Below 1000 seconds, the time resolution is 1 s. Between 1000 and 10000 seconds, the resolution is 10 s, and 100 s above 10000 seconds.

|

|

seconds (s), volts (V)

|

Init. Delay

|

The Initial Delay phase of the experiment is the first step to occur in the experimental sequence. This phase of the experiment stabilizes the open-circuit potential of the sample prior to any applied signal and measures that open-circuit potential.

The Initial Delay is turned On or Off via the check box in the Setup dialog. The Initial Delay Time parameter is the time that the sample is held at the open-circuit potential prior to the scan. The delay may stop before the Initial Delay Time if the Stability criterion for Eoc is met. The minimum Delay Time time is 1 s and the maximum time is 400000 s (more than 4 days). Below 1000 seconds, the time resolution is 1 s. Between 1000 and 10000 seconds, the resolution is 10 s, and 100 s above 10000 seconds.

In many cases, you really do not want to set a delay for a fixed time, but you may want to a delay until Eoc stops drifting. The Stability parameter allows you to set a drift-rate that you feel represents a stable Eoc. If the absolute value of the drift-rate falls below the Stability parameter, the Initial Delay phase of the experiment ends immediately, disregarding the programmed Initial Delay Time. Enter a Stability setting of zero to ensure that the delay will last for the full Initial Delay Time. A typical value is 0.05 mV/s. The upper limit of this parameter is 8 V/s, well above the range of practical stabilities with real cells, while the lower limit is set by your patience. A stability of 0.01 mV/s indicates a drift of less than 1 mV within 100 seconds. The software will always take data long enough to resolve a 1 mV change in the potential at the requested drift rate.

No open-circuit voltage measurement occurs if the initial delay is turned off. In this case, the open-circuit voltage defaults to 0.0 V.

|

|

seconds (s), mV/s

|

Estimated Z

|

A user-entered estimate of the cell's impedance at the Initial Freq. parameter. It is used to limit the number of trials required before acquiring the first data point in an impedance spectrum. It is generally sufficient if Estimated Z is within a factor of five of the cell's impedance.

Before taking the first data point, the EIS software sets up the potentiostat and frequency response analyzer (FRA) to measure an impedance equal to Estimated Z and tries to measure the cell's impedance. If the estimate is fairly accurate, the first (or second) attempt to measure the impedance succeeds. If the estimate is poor, the system may take up to five trial readings before it finds the correct settings:

•After the first data point, the last measured impedance is used to calculate new measurement settings, so the entered Estimated Z becomes unimportant.

•An accurate Estimated Z is more valuable when the initial frequency is low. Remember, 1 mHz is 1000 s per cycle. Each impedance reading requires at least three cycles at a given frequency, so five readings to find a range at 1 mHz will take over 4 hours!

•There is no reason to enter values larger than 1 TΩ (1012 Ω or smaller than 0.01 Ω, because these values drive the system settings to their most sensitive and least sensitive settings, respectively.After the first data point, the last measured impedance is used to calculate new measurement settings, so the entered Estimated Z becomes unimportant. |

|

ohm

|