LED Pstat (Master)

|

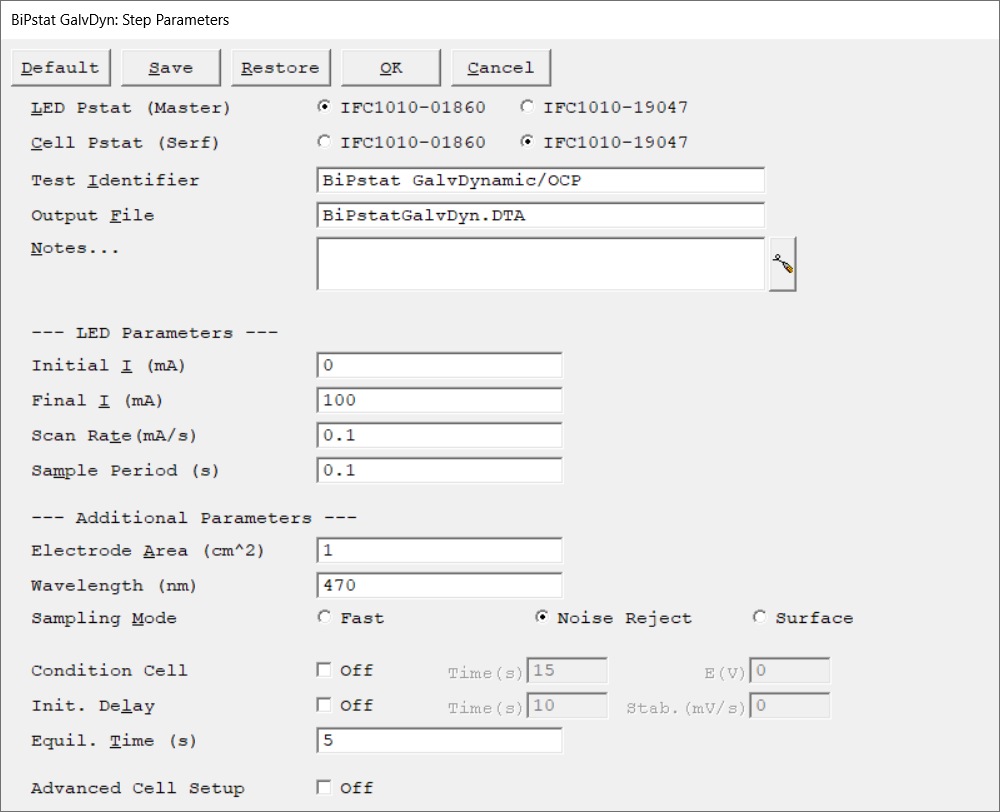

Select the potentiostat to control the LED. Each radio button corresponds to an installed potentiostat. You can select only one potentiostat at a time. Potentiostats that are already in use are marked with an asterisk. They can be selected but cannot be used. LED Driver (MASTER) and Cell Pstat (SERF) must be configured as a bi-potentiostat.

|

The LED Driver must be the MASTER potentiostat in the bi-potentiostat setup. The LED is galvanostatically controlled by this potentiostat. Selecting a wrong potentiostat may damage the LED.

|

|

|

Cell Pstat (Serf)

|

Select the potentiostat/galvanostat to perform the experiment. Each radio button corresponds to an installed potentiostat. You can select only one potentiostat at a time. Potentiostats that are already in use are marked with an asterisk. They can be selected but cannot be used. LED Driver (MASTER) and Cell Pstat (SERF) must be configured as bi-potentiostat.

|

The Cell Pstat must be the SERF potentiostat in the bi-potentiostat setup.

|

|

|

Test Identifier

|

A string that is used as a name. It is written to the data file, so it can be used to identify the data in database or data manipulation programs. The Identifier string defaults to a name derived from the technique's name. While this makes an acceptable curve label, it does not generate a unique descriptive label for a data set. The Identifier string is limited to 80 characters. It can include almost any normally printable character. Numbers, upper- and lower-case letters, and the most common punctuation characters including spaces are valid.

|

|

Output File

|

The name of the file in which the output data are written. By default, it is saved in the default file directory.

The input can be a simple file name with no path information. In this case the output file is located in the default file directory. The default file directory is specified in the Gamry.INI file under the [Framework] section with a Key named DataDir. The default path can be changed using the Path command in the Options menu. It can also include path information, such as C:\MY GAMRY DATA\YOURDATA.DTA. In this example, the data are written to the YOURDATA.DTA file in the MY GAMRY DATA directory on drive C. The default value of the Output File parameter is an abbreviation of the technique name with a *.DTA filename extension. We recommend that you use a *.DTA file name extension for your data file names. The data analysis package assumes that all data files have *.DTA extensions.

If the script is unable to open the file, an error message box, Unable to Open File, is generated. Common causes for this type of problem include:

•Invalid file name.

•The file is already open under a different Windows® application.

•The disk is full.

After you click the OK button in the error box, the script returns to the Setup where you can re-enter the file name.

|

|

|

Notes...

|

Enter several lines of text that describe the experiment. A typical use of Notes is to record the experimental conditions for a data set.

Notes defaults to an empty string and is limited to 400 characters. It can include all printable characters including numbers, upper- and lower-case letters, and the most common punctuation including spaces. Tab characters are not allowed in the Notes string. Press the Notes button on the right-hand side to open a separate Notes dialog box.

|

|

Initial I

|

The starting current of the scan segment.

|

All LEDs provided by Gamry Instruments require positive currents. Their maximum current is typically 1 A. In order to avoid any damage to the LED, stay within the current specifications of the LED.

|

|

mA

|

Final I

|

The final current of the scan segment.

|

All LEDs provided by Gamry Instruments require positive currents. Their maximum current is typically 1 A. In order to avoid any damage to the LED, stay within the current specifications of the LED.

|

|

mA

|

Scan Rate

|

The speed of the current sweep (actually a staircase ramp) during data acquisition.

A practical bound on the Scan Rate is about 10% of the full-scale current range per second. Higher Scan Rates may run but yield unreliable data because the potentiostat's compensation and filtering are set for long time constants. A lower bound on the Scan Rate is given by the minimum Step Size and the longest Sample Period. The minimum Step Size is 0.0033% of full-scale current and the longest Sample Time is 715 seconds. The slowest Scan Rate is therefore 55 ppm of full-scale current per second, or 0.02% of the full-scale current per hour.

|

The most sensitive current range on your potentiostat is generally not available in controlled-current experiments.

|

|

|

mA/s

|

Sample Period

|

The spacing between data points. The shortest Sample Period we recommend is 0.1 s. The longest Sample Period allowed is 715 s for Reference potentiostats and 750 s for Interface potentiostats.

The total number of points must be less than 262 143 (218 - 1). If you have more points, the experiment aborts just before the scan phase of the sequence.

|

seconds (s)

|

Electrode Area

|

The surface area of the sample that is exposed to the solution. The software uses the sample area to calculate the current density and corrosion rate (if applicable). If you do not want to enter an area, we recommend that you leave it at the default value of 1.00 cm².

|

Do not enter a value of zero!

|

|

cm2

|

Wavelength

|

The wavelength of the LED which is used for the experiment. This parameter is merely informative and not required for analysis.

|

nm

|

Sampling Mode

|

Select the sampling method for the experiment. Depending on the experiment type, choose between Fast, Noise Reject, and Surface mode.

|

|

Condition Cell

|

You may condition the electrode as the first step of the experiment, e.g., to remove an oxide film from the electrode or to grow one. Conditioning ensures that the metal sample has a known surface state at the start of the experiment. This step is done potentiostatically for a set amount of time.

Turn the conditioning phase On or Off with the Conditioning switch check box. Conditioning E is the potential applied during the conditioning phase of the experimental sequence. The conditioning potential has an allowed range of ±8 V. The resolution is 0.25 mV. If you have iR-compensation enabled for the data acquisition phase of your experiment, it is also turned on during conditioning. Conditioning E is always specified vs. Eref, because the open-circuit potential is not measured until after Conditioning is completed.

The Conditioning Time is the length of time that the sample is potentiostatted at Conditioning E. The minimum time is 1 s and the maximum time is 400000 s (more than 4 days). Below 1000 seconds, the time resolution is 1 s. Between 1000 and 10000 seconds, the resolution is 10 s, and 100 s above 10000 seconds.

|

|

seconds (s), volts (V)

|

Init. Delay

|

The Initial Delay phase of the experiment is the first step to occur in the experimental sequence. This phase of the experiment stabilizes the open-circuit potential of the sample prior to any applied signal and measures that open-circuit potential.

The Initial Delay is turned On or Off via the check box in the Setup dialog. The Initial Delay Time parameter is the time that the sample is held at the open-circuit potential prior to the scan. The delay may stop before the Initial Delay Time if the Stability criterion for Eoc is met. The minimum Delay Time time is 1 s and the maximum time is 400000 s (more than 4 days). Below 1000 seconds, the time resolution is 1 s. Between 1000 and 10000 seconds, the resolution is 10 s, and 100 s above 10000 seconds.

In many cases, you really do not want to set a delay for a fixed time, but you may want to a delay until Eoc stops drifting. The Stability parameter allows you to set a drift-rate that you feel represents a stable Eoc. If the absolute value of the drift-rate falls below the Stability parameter, the Initial Delay phase of the experiment ends immediately, disregarding the programmed Initial Delay Time. Enter a Stability setting of zero to ensure that the delay will last for the full Initial Delay Time. A typical value is 0.05 mV/s. The upper limit of this parameter is 8 V/s, well above the range of practical stabilities with real cells, while the lower limit is set by your patience. A stability of 0.01 mV/s indicates a drift of less than 1 mV within 100 seconds. The software will always take data long enough to resolve a 1 mV change in the potential at the requested drift rate.

No open-circuit voltage measurement occurs if the initial delay is turned off. In this case, the open-circuit voltage defaults to 0.0 V.

|

|

seconds (s), mV/s

|

Equil. Time

|

The duration during which the cell remains at the initial potential, with the cell turned on before data acquisition begins. It allows the system to equilibrate before the actual experiment starts. No data are recorded during this step.

|

The input parameter must be an integer. If equilibration is not required, set this value to 0.

|

|

seconds (s)

|

Advanced Cell Setup

|

The Advanced Pstat Setup checkbox, if checked, opens the Hardware Settings window, to control specific aspects about your hardware. If you are not an advanced user or simply wish to use the default hardware settings as specified in the scripts, just un-check this box. If you wish to specifically set some hardware items, check this box. The Hardware Settings window opens upon clicking the OK button.

|

|