Description

Parameter |

Description |

Units |

||

|---|---|---|---|---|

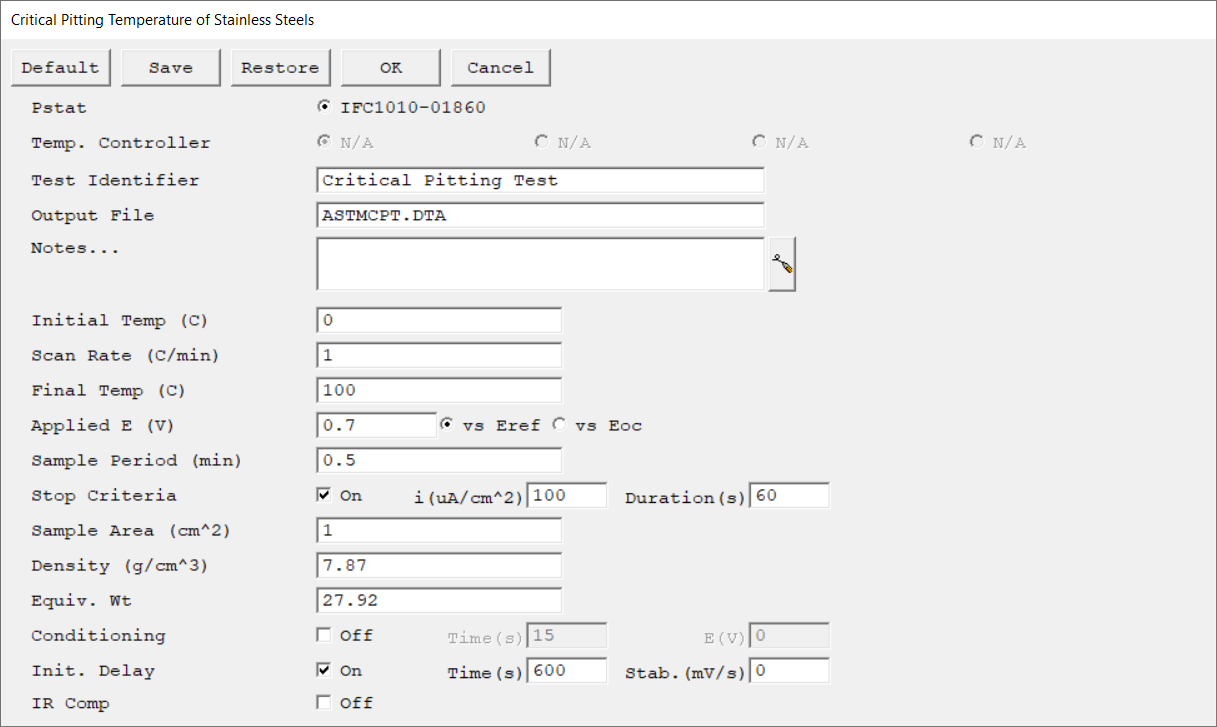

Select the potentiostat/galvanostat to perform the experiment. Each radio button corresponds to an installed potentiostat. You can select only one potentiostat at a time. Potentiostats that are already in use are marked with an asterisk. They can be selected but cannot be used. |

|

|||

Select the temperature controller for the experiment. Most Critical Pitting Temperature (CPT) systems have only one temperature controller, so this parameter may not be required. However, you may install support for more than one type of controller. |

|

|||

A string that is used as a name. It is written to the data file, so it can be used to identify the data in database or data manipulation programs. The Identifier string defaults to a name derived from the technique's name. While this makes an acceptable curve label, it does not generate a unique descriptive label for a data set. The Identifier string is limited to 80 characters. It can include almost any normally printable character. Numbers, upper- and lower-case letters, and the most common punctuation characters including spaces are valid. |

|

|||

The name of the file in which the output data are written. By default, it is saved in the default file directory.

|

|

|||

Enter several lines of text that describe the experiment. A typical use of Notes is to record the experimental conditions for a data set.

Notes defaults to an empty string and is limited to 400 characters. It can include all printable characters including numbers, upper- and lower-case letters, and the most common punctuation including spaces. Tab characters are not allowed in the Notes string. Press the Notes button on the right-hand side to open a separate Notes dialog box. |

|

|||

The temperature at which the experiment begins the increasing temperature sweep. The default range is 0°C to 200°C in 0.1° increments. |

degree Celsius (°C) |

|||

The speed of the temperature sweep. The range of practical temperature scan rates depends on your cell characteristics.

|

°C per minute |

|||

The temperature at which the experiment ends. If the current has not exceeded the limit at this or any previous temperature, the experiment ends. The default range is 0°C to 200°C in 0.1° increments. |

degree Celsius (°C) |

|||

The voltage applied to the working electrode during the measurement. Enter the voltage either versus the reference electrode potential (vs. Eref) or open-circuit potential (vs. Eoc). The allowed range is ±8 V with a resolution of 0.125 mV. |

volts (V) |

|||

The spacing between data points. The shortest Sample Period we recommend is 0.25 to 1 s.

|

minutes (min) |

|||

The Current Limit at which the experiment stops. The criterion must be met for the set Duration in order for the experiment to be halted. If the current drops below the limit prior to the Duration being exceeded, the counter is reset and the experiment continues. |

μA/cm2, seconds (s) |

|||

The surface area of the sample that is exposed to the solution. The software uses the sample area to calculate the current density and corrosion rate (if applicable). If you do not want to enter an area, we recommend that you leave it at the default value of 1.00 cm².

|

cm2 |

|||

The density of the metal sample, used in calculating the corrosion rate. You may disregard this parameter if absolute corrosion rates are not required for analysis. |

g/cm3 |

|||

Theoretical mass of metal lost from the sample after one Faraday of anodic charge is passed. One Faraday of charge is equivalent to an Avogadro's number of electrons. The Equivalent Weight can be used to calculate the corrosion rate. You may disregard this parameter if absolute corrosion rates are not required.

To calculate the equivalent weight for an alloy, you need to know: •The composition of the metal sample, expressed in mole fractions. •The atomic weight AW of each alloy constituent. •The number of electrons n, lost by each component of the sample as it oxidizes.

|

g/equivalent |

|||

You may condition the electrode as the first step of the experiment, e.g., to remove an oxide film from the electrode or to grow one. Conditioning ensures that the metal sample has a known surface state at the start of the experiment. This step is done potentiostatically for a set amount of time.

|

seconds (s), volts (V) |

|||

Use the Initial Delay parameter to tell the system your definition of a stable potential and when to begin the actual measurement. If the absolute value of the Eoc drift-rate falls below the Stability parameter, the Initial Delay phase ends immediately and the experiment begins, disregarding the Time parameter. The drift rate can never fall below zero, so entering a Stability value of zero ensures that the Initial Delay will not end prematurely. A typical value is 0.05 mV/s. The lower limit of the Stability parameter is set by your patience. For example, a stability of 0.01 mV/s indicates a drift of less than 1 mV within 100 seconds. |

|

|||

Choose to turn iR-compensation either On or Off. Turning on IR Comp causes the applied potential to be adjusted for the estimated iR-drop.

Gamry potentiostats are able to estimate uncompensated voltage-drop caused by cell resistance. They do so by performing a current-interrupt experiment after every data point. |

|